Transparency is a key goal of any business enterprise that relies on a complex supply chain. For organizations in the food and beverage industry, these goals have critical implications. In this blog post, we explore the reasons why enterprises should embrace supply chain transparency with a special focus on the food and beverage industry.

What is supply chain transparency?

The terms “transparency” and “visibility” are often used interchangeably, and their definitions differ across industries and organizations. Though often used interchangeably, visibility has a slightly different connotation. Traceability is a closely related concept.

Transparency

Transparency is making all information regarding the products and processes available to all stakeholders: consumers, partners, shareholders, and regulatory bodies.

Visibility

Visibility allows stakeholders to closely examine a product or a process at a particular link or a touchpoint in the supply chain. stakeholders: consumers, partners, shareholders, and regulatory bodies.

Traceability

Supply chain traceability is the ability to track the origin and journey of products, from sourcing and manufacturing to consumption, the end of the supply chain.

Meet consumer demand for transparent food supply chains

Today’s consumers are conscientious. They are motivated by health, wellbeing, and social issues and consider nutrition information, actual benefits, visibility into suppliers, treatment of animals, and environmental sustainability — and these motivations affect their buying decisions.

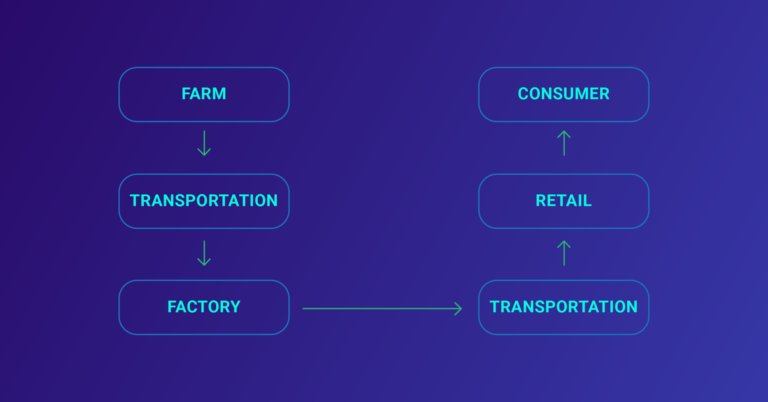

A culmination of this new thinking behavior is the farm-to-table social movement, which expects organically grown, fresh, local produce. These expectations put a lot of pressure on food and beverage companies. If a company fails to satisfy these needs, consumers have multiple alternatives to choose from: the competition is high.

Figure 1: Farm to table process

Transparency is extremely important or important to 81% of shoppers both online and at brick-and-mortar stores, according to Transparency Trends: Omnichannel Grocery Shopping from the Consumer Perspective, a report published by FMI and Label Insights, a product transparency market leader.

Supply chain transparency is an important differentiator, especially for food and beverage manufacturers and retailers. It helps build brand loyalty and trust.

Identifying and responding to food safety issues

From salmonella contamination in poultry to undeclared peanuts in granola bars, food and beverage safety issues can lead to serious health risks for the public. If you visit the web spaces of regulatory bodies such as the U.S. Food and Drug Administration, Rapid Alert System for Food and Feed (EU), and Food Standards Australia New Zealand, you can see a list of recalls for each region.

According to WHO, 351,000 people die of foodborne diseases globally—every year.

Even more people are hospitalized, and millions of people get sick.

As news of food recalls go viral, they jeopardize the years of trust and brand value food and beverage companies have built with partners and consumers. There is also pressure from regulatory bodies. For example, the United States’ Food Safety Modernization Act (FSMA) expects food & beverage companies to be proactive in preventing food safety issues.

Having a transparent and visible supply chain enables F&B companies to respond to food safety issues and recalls swiftly. With traceability, companies can trace problematic batches, lots, and shipments throughout the supply chain and take necessary actions to contain them.

Cutting down food waste and loss

The United Nations’ Food and Agriculture Organization (FAO) estimates the global volume of food wastage to be about 1.3 billion tons per year, which amounts to one-third of food produced for human consumption. This happens in a backdrop where nearly 870 million people are undernourished globally.

Food waste and loss can happen at any stage of the farm-to-table process.

| On the farm | In the factory | Transportation | In the warehouse | In the store | At the table |

|---|---|---|---|---|---|

|

|

|

|

|

|

On the farm

- Low produce due to weather and climate fluctuations.1

- Availability, quality, and nutritional aspects vary due to the seasonal nature.

In the factory

- Poor handling

- Lack of knowledge and training

- Obsolete processes and equipment.

Transportation

- Spoilage caused by delays

- Improper temperature control during transportation

- Improper storage during transportation

In the warehouse

- Pest infestations

- Improper temperature and humidity levels

- Poor planning leading to prolonged storage of products with a limited shelf life

In the store

- Limited shelf life

- Not meeting the freshness, color, flavor, and texture expectations

At the table2

- Expiry

- Overbuying

2 Average U.S. household wasted 31.9% of its food – American Journal of Agricultural Economics The ability to easily track the source and usage of raw materials, ingredients, and finished food batches across all the above stages is key to understand how, when, and where food loss and waste happens in the food supply chain.

Meeting compliance and regulatory requirements

Public health is a high priority for governments and policymakers. Newer regulations require agile responses to food recalls and the manufacturer’s ability to trace products quickly. For example, under the Food Safety Modernization Act of 2011, the US FDA will have the authority to require traceability for selected high-risk food items. Australia’s National Livestock Identification System (NLIS) mandates the identification and traceability of cattle, sheep, and goats throughout their lifespan. European Food Safety Authority has laid down similar measures.

Also, regulations change often; having supply chain transparency and traceability enables manufacturers to adapt to new regulations and provide the information required for doing business with new markets, quickly.

Sustainability beyond the farm

While sustainable and environment-friendly farming practices play a critical role, sustainability matters beyond the farm, throughout the food supply chain.

The sustainability goals in the food supply chain are under challenge due to the growing world population and resource scarcity. Adding to the woe, if ecosystems continue to degrade at the current rate, we will soon reach a point of no return.

On the farm, food manufacturers practice crop rotation to preserve soil health and to prevent soil erosion. Methane, a greenhouse gas emitted by dairy cows, affects the earth’s temperature and climate stability. A 2015 study showed that adding seaweed to cattle feed can significantly cut down methane emissions. Similarly, many novel technologies have been implemented to improve sustainability during transportation, warehousing, and retail.

For F&B companies, sustainability is no longer a trend but a business imperative for better profitability, long-term viability, and, most importantly, to safeguard the wellbeing of consumers. And to identify, plan, implement and optimize sustainable practices throughout the food supply chain, transparency and visibility play a key role.

In the next blog post, let’s explore how enterprises can use the cloud, business intelligence, analytics, and Industry 4.0 technologies to improve visibility, transparency, and traceability across the food supply chain.

References:

- Estimating Food Waste as Household Production Inefficiency, American Journal of Agricultural Economics

- Best Practice Guide: Improving supply chain transparency in modern food and beverage manufacturing, Infor

- Report: Incentivizing Food Systems Transformation, World Economic Forum in collaboration with McKinsey & Company

Related Blogs

Subscribe to our blog to know all the things we do