During the past 9 years I have participated in many ERP selection meetings, project kick offs and lessons-learnt sessions. The primary question we pop at CIOs is: What are the key benefits your organization wants to realize from this project?

The question, which seems straightforward in the beginning becomes challenging and even a distressing question towards the end of the project. If the project does not proceed according to the schedule or the scope, things get further complicated. To answer this question effectively, it is necessary to come up with a broad business case and a benefits realization plan justifying the ERP project cost and assurance of ROI. Statistics in 2015 show that companies often fail to realize the benefits of an ERP implementation due to improper planning.

A smart CIO should lay out a plan measuring the outcome of the project before beginning an ERP implementation project. This activity could be a very time-consuming task requiring a lot of effort; however, it is recommended to perform this task before initiating an ERP project. This will also justify time spent on implementing a solution, the money spent on a particular product and help you determine the achievable scope of the project.

Before implementing and ERP solution, you should pay attention to the following ten pain points:

1. Availability of information

Availability of information refers to a user’s ability to access business information whenever and wherever required. But, there is more to information availability; CIOs should identify the KPIs that allows an organization to gain valuable business insights. Frequently malfunctioning system and improper security measures greatly affects the information availability. Another parameter to consider is the ease of retrieving information. A system will not be complete if it doesn’t assure high availability of information and ensure business continuity in a disaster. A comprehensive risk analysis should be performed and it is advisable to invest in a disaster recovery plan.

System uptime statistics, response times, disaster recovery options, coverage of all business critical systems must be considered before determining KPIs.

2. Reliability of Data

Information available in an ERP system should be consistent and accurate. The ability of an ERP solution to extend its functionality by automating processes and removing manual intervention increases the reliability of data. Testing and retesting data using multiple tools and resources could help an ERP implementation team to evaluate the data reliability. How do you ensure data is reliable? Test-Retest: During a “dry-run”, the ERP business team may run a report twice to see if the same output is achieved. It can go on to many further iterations by changing the resources and methods to generate different outputs. Comparison: There maybe a number of examples illustrated in a company’s historic business studies or analysis reports; either this information or the current information already available within an organization can compared with the new data and processes. This process is repeated until it reaches a satisfactory level. Even though this method is commonly used, the high chance of deviating from best-practices is a drawback. Parallel run: “Parallel run” is another strategy where the newly implemented system and its processes are run parallel to the legacy or manual systems. This method can be adopted to evaluate two versions. Rating: I call this the “judgement by SMEs”. When all of the above three methods are unable to evaluate the ERP system, a panel of subject matter experts may judge the set of data and assign an appropriate rating. These values and rates may be documented and reanalysed whenever discrepancies arise. Do not forget to touch upon data validity: Having only reliable information doesn’t necessarily guarantee a successful ERP system. Processing only valid data is the crucial factor. A good gap analysis will reveal whether the data should be processed and whether it is relevant to key operational activities. Reliable but invalid data, simply, is not useful. A system should produce both accurate and valid data. As a consultant, I use the following proven questionnaire to evaluate the validity of a data set:- How did you produce this report? Who prepared it?

- Why do you receive it?

- Who is the intended audience? (Subject matter experts often come up with reports which they didn’t know to whom they were prepared for.)

- What is the purpose of the report?

- Who approved the report?

- How long is the cycle time of the report?

3. Increased interaction and integration between the departments

I would like the company CIO to tell me how they (the CIO and the ERP team) are going to achieve this goal through the ERP system. Our ERP consultants will then, walk them through the process maps and identify what needs to be accomplished, covering areas critical to business processes and systems. The ERP solution should have the capability to interconnect organizational processes and its third party stakeholders and, independent systems.

Also look into:

Improved customer interactions: How will the new ERP system improve the interaction between the organization and its customers?

Can the capabilities of EDI (Electronic data interchange) technology integrate to the ERP system to deliver better value and interaction with clients?

Improved supplier interactions: As a manufacturing plant, can you facilitate your vendors the same way you receive orders to optimize your business channels? Can the ERP send purchase orders automatically and remind suppliers of required revisions in a timely manner? These are some of the aspects you can dig deep to enhance communication and optimize relationship with external parties.

4. Improved productivity and efficiency

This is the most common goal I have come across in business benefits realization plans. The approach that certain organizations take to achieve these KPIs varies from simple to very complex. Irrespective of the estimated duration to meet both targeted productivity and efficiency levels, the business team must share the plan with the vendor as early as possible. This will help the team determine how much time the project needs to realize targets with a plan broken to weeks, months and years. The following paragraph describes an example scenario where a team came up with an exercise to determine the reduced cycle time. Technique used was observation. A merchant took an average of 24 minutes to receive a garment order and then to split the garments into different colours and sizes using Microsoft Excel and a calculator. In a pilot run of the ERP system, it was observed that same merchant took 5 minutes to achieve the same results. The chance for error ratio was reduced from 5% to almost zero by automating the processes. When integrating processes to an ERP system, it is important to determine the nature of the processes based on the activities within a process. One process may include scheduled activities (e.g., shortest path algorithm to meet end goals such as ex-factory and shipment handovers) while another process may include ad-hoc activities requiring unplanned work. This determination will allow the management to better control and monitor activities which are both critical and not-so-critical to increase the productivity.5. Making better informed decisions

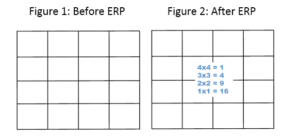

How many squares do you see?

Figure 1: Before ERP

In the above example, the grid under Figure 1 needs much more work to determine the number of squares that is 30. Figure 2 simplifies the same task by providing additional information.

To increase the efficiency, identify factors that enhance decision making and eliminate those that hinder a quick consent between two parties. Identify and enlist features that need to be in your new system to enable a transparent collaborative environment. A lengthy meeting can be quickly transformed to a fact-based short analysis with the supporting data from your new system.

6. Less duplication of effort

Good systems not only reduce redundancy of tasks but catch and kill tasks that result in lesser productivity. A centralized repository should facilitate multiple resources to work together seamlessly. How many new features will help your organization to get going with the concept of re-usability?7. Improved lead-time and inventory levels

The business study must clearly show figures such as target lead times. Once end users are comfortable with the new system, the productivity and satisfaction levels will grow exponentially. However, it is always good to have a clear illustration of these figures beforehand to help with the post implementation.8. Reduced maintenance costs

Mainly, this refers to the reduced IT maintenance cost. The debate on selecting an on premise hosting to cloud hosting takes place much earlier on the ERP vendor selection process. The success of an ERP implementation depends on the outcome of these decisions. It is always useful to gather information of indirect operations’ cost that can be reduced by the new implementation. The importance of information generated by indirect operations can get lost with the hype of the ERP implementation.9. Compliance

How can the globally recognized standard software lead my way to support certain regulatory and statutory needs? is another question that should be answered and an important area to be considered in business.10. Going with the flow

Your competitor just completed an overwhelming ERP implementation at their premises and you witnessed the buzz it created. Should this be a reason for you to implement an ERP system? Certainly not. Unless luck plays a part, going with the trend will only result in unpleasant unforeseen surprises. That’s it. Good luck with your next ERP project. In this article, I have explained 10 tricky areas that need to be considered before thinking about going ERP. I have stressed more on the reliability of information because the last thing that an implementer wants to hear are system failures and expectations not being met. The main drawback of a quantitative approach of measuring reliability is that there is a chance to manipulate numeric figures due to time constraints in ERP projects. Learn and test your system as early as possible. It is advisable for a project manager to be mindful about these aspects and allocate more time to set up a realistic project plan. Author: Tharake Jayalath – Associate Project Manager, Manufacturing Tharake engages in Brandix i3’s ERP product – Accellar optimizing the solution to provide a technological platform that would enable a manufacturing plant to best achieve its business goals. He has been the industry for last 9 years as a developer and then project manager and have garnered a proven track record of successful delivery. References: **The ERP report 2015 by Panorama Consultancy, Technopedia, SagePub, Uni.edu Other website references: https://www.techopedia.com/ https://www.uni.edu/ https://www.sagepub.com/ Presentation by Veritas / Presentation by Sungard Ability Services- Availability of information

- Reliability of Data

- Increased interaction and integration between the departments

- Improved productivity and efficiency

- Making better informed decisions

- Less duplication of effort

- Improved lead-time and inventory levels

- Reduced maintenance costs

- Compliance

- Going with the flow

Related Blogs

Subscribe to our blog to know all the things we do