This blog post is a continuation of a two-part article on fashion and sustainability. Read part 1: Reset Retail: The pandemic and shifting customer expectations

Mapping the fashion business process to an integrated software solution

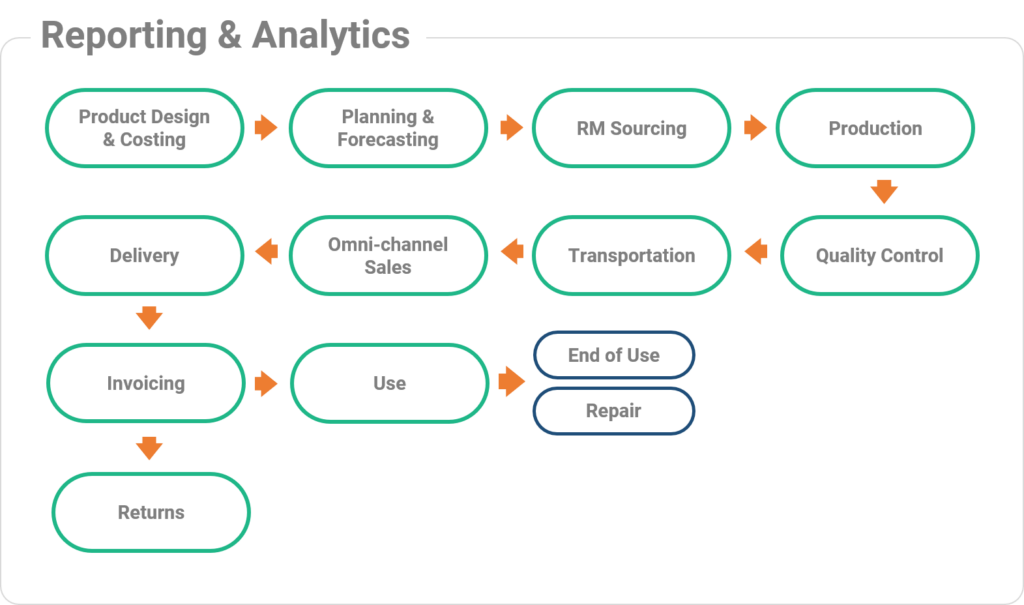

A fashion product’s basic business process can be defined as follows:

.

The first and most important thing to ensure a product is truly sustainable, is a transparent end to end business process. Keeping an arm’s length from the supply or production process of a product can lead to unknown sustainability issues. Or worse still, data silos on disassociated servers or spreadsheets in a tangled web of version mismanagement can make it impossible to trace back the history of a product, even if it has been recorded. The easiest way to keep things manageable is to have a system of record that connects the very first step to the very last, including every step in between. Using an appropriately implemented system, it should be possible to pick up a t-shirt on a shelf in a Regent Street shop and trace back the exact Bangladesh shop-floor on which it was made, and the exact cotton farm the thread came from.

In organizations that have an integrated end to end system of record, multiple modules are utilized for managing such a complex process. From a sustainability point of view, the key systems include a Product Lifecycle Management (PLM) system for product design and RM sourcing, an Enterprise Resource Planning (ERP) system for other core functions from production through to invoicing and a reporting and analytics system. These systems are interfaced together, with other add-ons being integrated based on need and could include a warehouse management system, Point of Sales (POS), demand management and e-commerce. More recently, many of these systems are collaborative spaces, facilitating both inter-company and intra-company dialog and data exchange in an easy manner.

As in the FRIB system, my reference system for PLM is Infor’s PLM for Fashion, the ERP is Infor’s Cloudsuite Fashion and the Analytics system is Infor Birst. It may be expected, however, that best of breed comparable systems should be able to perform similarly.

The Sustainability Score – a way to monitor sustainability throughout the organization

Mark Harrop, founder and CEO of WhichPLM, explained in a recent webinar, that a sustainability score could be used to denote the sustainability of a product’s components. He elaborated that an extended Bill of Materials (BOM) is an ideal way in which a PLM system can be utilized to support sustainability. A BOM lists all the components that constitute a product – every fabric, trim, button and thread – as well as every sewing and packaging action. Extending this to allow for a sustainability score for each component, would allow the system to manage the sustainability of a product. Calculating a sustainability score is not an easy task. A paper titled, “Sustainability Initiatives in the Fashion Industry” illustrates this by comparing cotton with polyester. Polyester has a carbon footprint that’s more than double cotton. But cotton produces a water footprint 20 times that of polyester. Thus counterintuitively, for an organic cotton cloth bag to make up for the environmental impact of a clear plastic bag (in terms of energy and water use), it would need to be used 20,000 times.

Regardless, even though hard to calculate, the clearest method for managing, comparing and making companywide and cross-product decisions regarding sustainability would be to have a scoring system that applies to all finished products.

There are many bodies that specialize in the formulation of sustainability indexes and scores. Industry standards such as the Higg Material Sustainability Index (MSI) and other Higg product and facility modules are attempting to lay a solid foundation upon which companies can assess the sustainability of their designs and raw materials. Other standards provide re-useable sustainability data on commonly used raw materials such as the MADE-BY Environmental Benchmark for Fibers which compares the environmental impact of 28 commonly used fibers. It is also possible to work with external bodies to calculate sustainability scores for an organization’s products, such as Nike does with the Nike Apparel and Footwear Sustainability Indices. Using reputed and globally recognized indices is one way to have a score that is meaningful outside the organization as well as within it.

It seems logical that as the demand for data on sustainability throughout the fashion process increases, the tools with which to calculate a score will also increase.

If a company adopts a scoring system, at the outset it might only be applicable to a small subset of a collection. But as the trend towards sustainability gets more established, the system can be expanded to include more products and eventually all products.

The scoring system, therefore, could be incorporated even further into the system – by assigning a sustainability score to every key element involved in the end to end business process of a fashion product. This could then be used in a multitude of ways to manage sustainability policies and decisions within the organization.

Product Lifecycle Management (PLM)

The PLM system is usually the birthplace of a product and thus it is the most important system for managing the sustainability of a product. PLM has become almost a necessity for any brand. The system covers everything from initial mood and story boards to detailed BOMs and supplier information.

If a retailer sells products that they do not design, they may not require a PLM system at all. But a PLM system with detailed information was probably utilized by their upstream suppliers.

As Mark Harrop suggested, the BOM in PLM could contain the sustainability scores of components. But this could be taken further, by using these values to calculate a sustainability “score” for the product, using the Higg module or something similar.

Every raw material in a PLM system has a master data element associated with it. For example, a fabric would have a fabric master record which contained detailed information such as composition (60% cotton, 40% polyester), color and UPC/EAN code. The sustainability score, which encapsulates the sustainability of every part of that fabric from its dyes to the cotton farming process, could be attached to its master data.

To make the score re-usable, instead of attaching it to a BOM, it can be attached to each raw material instead. Then any BOM which uses that raw material will carry through the RM’s sustainability score, reducing the need for duplicate data entry.

Let’s imagine that a red floral print fabric has a particular sustainability score. If this data was saved in the fabric’s master data, when it is used in a BOM for a t-shirt or the BOM for a matching skirt, the score will be carried across from the master data to the BOM.

Similarly, every supplier in a PLM system also has a master data element associated with it. For example, a supplier would have a supplier master record that contained its name, address and billing information. A sustainability score, which encapsulates the sustainability of the supplier – everything from the supplier’s energy efficiency and GHG emissions to their labor practices – can be attached to the supplier master data. This could be taken further by linking supplier certificates, such as FairTrade and BCI, to the supplier master record. Supplier compliance tools allow capture and upload of testing and audit information, quickly and easily so it can be retrieved whenever needed. All such data could be used to calculate the supplier’s score.

Taking our t-shirt example further, imagine the t-shirt could be made by two different suppliers with difference scores. Then the overall sustainability of the t-shirt would vary depending on the supplier chosen.

Thus, by assigning sustainability scores to suppliers and raw materials, designers have a way of assessing the sustainability of their design when putting together its BOM.

When it comes to assessing the economic viability of a product, users would be able to create alternate BOMs within the PLM system. In the alternate BOMs, different RMs and different suppliers could be assigned, some with differing sustainability scores, to calculate and compare the cost implication of a decision supporting higher sustainability.

Once the product is finalized, the product’s master data, linked to its own unique EAN/UPC code, can have a sustainability score. This reflects the overall sustainability of the product, calculated using a standardized index that considers the suppliers, the related manufacturing processes and raw material information.

Core ERP processes

The master data created in PLM is next interfaced into the core ERP system. This means that the sustainability information captured will be available right throughout the business process, including end consumer sales and delivery.

It is also possible to extend this concept of a score further within the ERP system. The Purchase Order processes, and Sales Order processes can be extended to carry sustainability scores. These can be automatically populated based on the suppliers used, the products or RMs ordered and the modes of transportation used. If for example, a user chooses air as the mode of transport, an automatically populated low Sales Order sustainability score could be designed to trigger an approval or review process by a manager.

As calculation algorithms get more advanced and accurate, it can be imagined that Batch Management could be extended to include sustainability score information. This would take the

generic sustainability score of the product and update it with an actual sustainability score based on the true processes that occurred during the production and transportation of a particular batch of a product. For example, if a shortage resulted in a supplier change or a mode of transportation change. This would allow complete sustainability traceability of the end to end process, including all countries of origin, supplier and raw material details

Analytics

Data capture is ultimately pointless if there is no clear way of accessing and using the data. A reporting and analytics system that captures sustainability scores, together with all the other data required, can ensure that sustainability is monitored and managed. Reports, KPIs and scorecards can be enhanced to include sustainability scores, which in turn can be used for strategic decision making and performance measurement.

Data collected on repairs, recycling and resale of a used product could increase a product’s sustainability score, giving further incentive for pursuing these strategies. A drawback, however, is that factors such as how many items of a product end up in landfill should affect the product’s sustainability scores, but such data is impossible to collect at such a specific level.

Managers and executives can use self-designed ad hoc reports as well as standardized companywide analytics to monitor the sustainability of the business. Full transparency will highlight any deviations during the end to end process, allowing for issues to be resolved mid process, resulting in a flawless sustainable flow of goods.

Having access to the data behind all the various modules in the integrated system, the reporting and analytics tool can be used to give consumers the true history, including all sustainability scores, of the t-shirt they picked up in the shop on Regent Street. A truly transparent end to end process

The options are limitless

Once sustainability scores are maintained throughout the system, they can be used for a myriad of functions. Customer loyalty programs could be linked to an order’s sustainability score. Discounts can be given for higher sustainability scores. Employee reward schemes can be based on sustainability scores. I could go on, but my excitement is about to get the better of me.

Sustainability after the pandemic

The pandemic gets blamed for a lot of things and rightly so. It is an unparalleled global event that will have negative repercussions for decades to come. But it has also given us, who are lucky enough to have got through it unscathed, a fresh perspective on things that matter. Spending more time with our kids, eating home cooked meals, going for a long evening walk. Sometimes all that’s needed to notice a wrong that’s staring you right in the face, is to be jolted out of your comfort zone for long enough. Embracing sustainability should not be with the intention of making bigger profits or beating the competition (although those would be fortunate side-effects). It should be because it is the ethical, responsible thing to do. Child slavery should not exist in 2020. Pesticides that kill indigenous life should not be used to make a t-shirt that gets worn for a month and then chucked in the bin to end its life in a landfill. We really do not need so many low-quality cheap clothing items. And we definitely do not need it at the expense of our planet or other less privileged people’s suffering. Let’s heed the message we are hearing again and again and again. Let’s not resort to the same excuses. Let’s turn our industry into something we can be proud of again by doing all we can to make it sustainable.

Written by:

Monalee Wonnacott

Senior Consultant - Infor Services, Fortude

Related Blogs

Subscribe to our blog to know all the things we do